Development Affordable Prosthetic Hand

| ✅ Paper Type: Free Essay | ✅ Subject: Technology |

| ✅ Wordcount: 3123 words | ✅ Published: 23 Sep 2019 |

Affordable Prosthetic Hand

Executive Summary

Many developing countries, such as Afghanistan, have a high percentage of amputees. Members of these countries can face discrimination, may not be able to attend school work or extracurricular activities. As a result, handicapped individuals and their families may face financial, physical, and mental struggles. Designing a prosthetic hand may result in a better quality of life for amputees and their families. A prosthetic hand would make it more likely for the amputees to find employment and education, thus improving the community. To ensure that the prosthetic is accessible for all, it must be affordable within an unsteady income, use unconventional energy and be durable.

Table of Contents

1.3 Criteria and Specifications

List of Tables

Table 1 – A table demonstrating the criteria and specifications of the prosthetic hand.

List of Figures

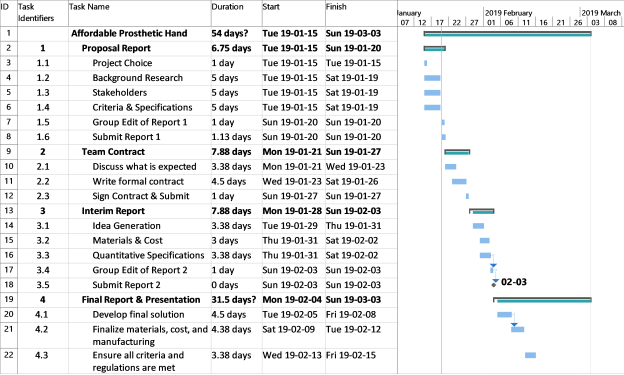

Figure A 1 – A capture of the Gantt Chart used to plan this project.

1.0 Problem Definition

Afghanistan, a war-torn developing country, has a high amputee population. Many individuals in this community do not have the financial or medical resources to seek treatment. Thus, developing a prosthetic hand for those with a residual forearm would be beneficial to the client and their community. This prosthetic must be durable, safe, comfortable, easily usable and maintained. It should consist of a simple adaptable design so that technicians can manufacture and repair the device easily. The prosthetic must be low-cost so that individuals can afford to buy and maintain the device based on an unsteady income. The energy required for the device must omit any use of conventional electrical energy storage. This device significantly impacts the client, specifically residual forearm amputees in Afghanistan by improving their quality of life. It affects the manufacture and distributor with regards to available materials, and ease of construction. The government is largely associated as the implication process needs funding. This device is determined successful if all above criteria are met and the overall environment for residual forearm amputees within Afghanistan is improved.

1.1 Background Research

This section consists of the background research required to develop the prosthetic hand.

1.11 Afghanistan

As the war continues in Afghanistan, the country and population continue to suffer. The amputees of Afghanistan are nearly entirely spurred from war wounds such as land mines yet continue to fight because they need to provide for their family. Given Afghanistan’s unstable situation and underdeveloped economic state, work opportunities are not readily available for many if it is not as a soldier. As it is a farm-based economy, employment is largely based around ranch hands, herdsmen or gardeners [1]. Amputees can potentially do physical labor work, but other times are not given the opportunity and are forced to the streets to beg for money.

As one of the least developed countries in the world, the medical care in Afghanistan is subpar.

Habitants often are forced to travel outside the country to receive the attention they need. For women it is even more so difficult to receive care as the Taliban have stripped their power entirely forcing them to be accompanied by men when leaving their home [2]. In addition, over a third of the population lives in poverty which restricts their ability to travel to suitable hospitals and care centers, sometimes forcing them to go without care. There has never been a government initialized welfare program nor any attempt made to benefit the population. The implication of a prosthetic leg by the ICRC (International Committee of the Red Cross) drastically improved the quality of life of those in need providing them with social benefits such as employment opportunities however there is still not a solution for the hand and forearm [3].

The human hand can perform a multitude of distinct tasks. Depending on the joint, members of the hand can rotate in one or two dimensions with varying ranges of motion [4]. For example, the wrist can rotate in flexion and extension and ulnar flexion and[4][4]. The combination of individual joint rotations creates movements that can perform tasks such as cylindrical and spherical; grasping, tip and palmar pinching, hook and snapping etc [4]. The goal when designing a prosthetic is to replicate certain movements that are most useful to an amputee. The specific movements which the prosthetic should be capable of will need to be considered based on complexity, stresses applied, usefulness, and ease of use for the user. Movements that are most useful in this application are defined as movements that are highly used by the user that best improve the user’s quality of life.

When designing a new prosthetic, it is important to consider the materials and the structure. The product should be aesthetically pleasing, waterproof and lightweight, yet very durable and strong. All these design criteria rely on the materials chosen for the design, thus it is especially important to understand the specific properties of each material used. Properties such as compressive, tensile, shear and torsional strength as well as shock absorption are important properties to mimic a real human limb’s movement [5]. Fatigue resistance, creep and resistance to corrosion are important properties to possess when designing a comfortable and lasting prosthetic [5]. Lastly, it is important for a prosthetic design to be biocompatible with the amputee. A prosthetic’s biocompatibility speaks to the materials agreeability with the surface of the amputee’s skin and living tissue [6]. A material that is not biocompatible with living tissue will cause discomfort and stress in the amputated area [6].

Metals have been used for prosthetic limbs since the Dark Ages, as they are more durable than previously used material such as wood and leather [6]. Alloyed or pure aluminum, titanium, magnesium, copper and steel are all used for various applications. Titanium metal is the main metal used because of its advantageous properties. Specifically, titanium is resistant to corrosion making it biocompatible and very strong while still lightweight [6]. When titanium is alloyed with other metals such as aluminum, it acts very similar to a bone because of its decreased elastic modulus [5]. Since metals are inherently very durable and strong, they tend to require less maintenance and last a long time, which is very economically favourable [5].

Hard and soft polymers are used for small specialized features in a prosthetic such as joints and phalanges [6]. Common polymers such as polyethylene and PVC have specific properties that benefit the functionality of a prosthetic. For example, polyethylene is a soft plastic that is used in a large quantity to make the prosthetic waterproof [6]. Moreover, poly vinyl chloride or PVC is very durable inexpensive option, however it does not respond to heat and light well [6].

Carbon Fibers are a recent addition to prosthetic design. Generally, carbon fibers have a high tensile strength and are resistant to corrosion, while being significantly lighter than any metal [7]. Carbon fiber composites move and respond similarly to a human muscle because they have high compressive and tensile strengths in addition to a high elastic modulus [7].

Supporting materials are used to increase biocompatibility for any material [6]. Due to their elastic properties and frictional relationship with skin, supporting materials act as a buffer to distribute mechanical stress and prevent painful side effects.

1.14 Unconventional Energy

Unconventional forms of mechanical energy storage that have the ability to be implemented to the prosthetic arm include compressed gas and elastic energy [8]. Although both forms of energy storage of usually applied at a larger scale, they can be scaled down for prosthetic applications. In the instance of compressed gas, the user could refill the compressed air cartridge using a finger pump. In the instance of elastic energy, the user could re-load the elastic storage device using a hand winder.

1.15 Patents

There are multiple prosthetic hands that currently exist within the medical world to date. Most of these devices follow similar concepts but consist of different mechanisms. It is important to understand the different types of hand prosthetics that exist when designing a new prosthetic. Three prosthetic designs were researched that correlate to the constraints of this project.

A designed by J. E. Conzelman Jr. et al. consists of a prosthetic hand that can be easily attached and detached to and from the forearm, allowing full elbow and shoulder motion. A simple locking mechanism with minimal linkage is used to grip objects, that once applied must remain in position without any external forces. The centre of gravity of the prosthesis is located near the elbow to reduce the apparent weight of the overall device. To avoid muscular exhaustion, a light material and an attachable shoulder harness is used. To ensure that customers are satisfied with their prosthesis a natural appearance is used which simulates natural movements [9].

A hand prosthetic created by Belter et al. consists of removable pin joints within the index finger, secondary finger, and thumb to allow for three distinct grasping behaviours. The thumb consists of multiple locking positions which correspond to different grasping formations. Grip pads are used on the bottom of the hand to assist with grasping objects. Helical torsion springs and elastic flexure joints are used to keep the hand opened. A harness is used to control the movement of the hand via movement of the shoulder [10].

A mechanical hand prosthetic created by Ryan William Glasgow consists of a body powered prosthetic with five operational fingers, including an opposable thumb, used to grasp objects. This device is designed to connect to various prosthetic arms to allow for comfort and choice of the client. Each finger is made from a series of diverse connections to allow the device to be scaled. The device is created using the least amount of components to minimize weight and simplify the manufacturing process [11].

1.16 Laws and Regulations

There are no existing laws or regulations with regards to prosthetic manufacturing or distributing within Afghanistan. As a point of reference, the regulations of prosthetics within the United States of America will be used. According to their code of regulations, prosthetics are exempt from the general requirements of the Federal Food and Drug Agency (FDA), including premarket approval. Companies do need to keep their records for FDA inspections and maintain complaint files [12]. This will be recognized when designing the prosthetic hand.

1.2 Stakeholder Needs

Client- As the user of this product the amputees of Afghanistan are the directly affected by the availability of a prosthetic hand in their society. Without an affordable solution to their defecate, amputees are often either physical labor workers, such are farmers or herdsmen or they rely on begging in the streets for day to day survival. However, with an alternative to their problem such as an affordable prosthetic, the individuals would receive a second chance in society offering them more employment opportunities and less discrimination. The product would need to be that of which can perform adequate actions of which a generic hand can achieve in addition to being as subtle as possible to avoid social stigma and pity from others.

Manufacturer- Ideally the product will source its resources locally, to avoid shipping costs. Once present, manufactures will need training, materials, specs and tools in order to create mass numbers of the product. As every individual with an amputation is different the manufacturers will focus more so on the average with lenience in the design for the largest accommodation in the population.

Community- The implication of a prosthetic effects the entire community. The number of readily available workers will drastically increase as well as a decrease in the number of beggars in the streets. This alone will be a stepping stone to not only improve the appearance of the country of Afghanistan, but help their path to recovery. For this to occur, the community must not pity nor ridicule those with disabilities which is why the aesthetics of the product is key.

Distributers- The distributors will be the medical professionals of Afghanistan. They must require the expertise and understanding of their patients needs to ensure the product is correct for their situation as well as any addition modifications to the product if required. For this, they need training, and experience.

Government- As there will need to be funding for the materials, worker pay and training for those involved in the process, the government will be asked for financial assistance. The ICRC (International Committee of the Red Cross) has a very good baseline system for leg prosthetics however they lack the forearm and hand. A low cost affordable, mass producible system is needed for the hand and arm. The government will need adequate testing and assurance that the product will be capable of achieving tasks by the workers they allow to work.

1.3 Criteria and Specifications

This section consists of a detailed criteria and specification analysis developed from research and the stakeholder needs.

Table 1 – A table demonstrating the criteria and specifications of the prosthetic hand.

|

Criteria |

Specifications |

|

Mobility |

The prosthetic should not restrict any body movement or functions. The prosthetic should move easily without causing strain to the rest of the body. |

|

Aesthetic |

The prosthetic should look and act similarly to a human hand. In addition, the prosthetic should be waterproof so that the product is hygienic and can easily be maintained. |

|

Safety and Comfort |

The material and design of the prosthetic must not cause painful side effects at body support interfaces. The user should not feel pain or discomfort during or after using the device. |

|

Adaptability |

The prosthetic should be easy to manufacture and intuitive. Each client should be able to use the product easily with little training. |

|

Cost |

The initial cost of the prosthetic must be affordable with respect to the average income of an Afghanistan family. The cost to maintain and repair the aid should be small and infrequent. |

|

Energy Source |

The prosthetic must be powered solely by an unconventional energy source. The energy source must not be a variable cost; thus, energy should be free for the user. Energy should be stored within the prosthetic. |

|

Materials |

The prosthetic may not be 3D printed. Instead, only locally sourced materials should be used to manufacture the prosthetic. |

|

Government Regulations |

Since there are no current laws concerning manufacturing and distribution of prosthetics in Afghanistan, the prosthetic will follow the laws and regulations set by the United States of America [12]. |

2.0 Project Plan

To ensure that this project is successful, a project plan was created by the team. A minimum of one meeting per a week, outside of class, will occur to discuss and designate tasks. Each team member is expected to complete his/her work on time, be punctual for each meeting, and actively participate. If a member cannot attend a meeting, he/she must notify the group in advance. The team will use a shared Word document to complete each report. All submissions will be group edited prior to the due date.

A Gantt Chart, displayed in Figure A 1 in Appendix A, is used to break down each task and demonstrate their respective due dates. There are four major submissions; the proposal report, the team contract, the interim report, and the final report and presentation. Each major task is then broken into minor tasks that must be completed. Some of the latter reports do not have detailed components as the instructions for those submissions have not yet been provided.

3.0 Early Economics

Economic considerations overarch into all elements of a design project and in turn, greatly impact the final product.

The materials used in the arm must be both lightweight and strong, although these aspects come at a high expense. The implementation of high-performance materials will increase the lifespan of the prosthetic, reducing the user cost of a hand replacement. Due to the low-cost constraints of the project, the cost versus performance for materials must be considered. The use of materials that can be broken down and reused would provide environmental benefits and allow the sale price of the prosthetic to be reduced due to lower material costs. The increased cost of manufacturing the arm using reusable materials versus the product sale price discount must be taken into consideration. Also, for the components that are not reusable, the disposability of the components must be taken into consideration.

Manufacturing location can have a large impact on the overall sale price of the prosthetic. The prosthetic could be manufactured in the Asian geographical area in a manufacturing focused country such as China, Taiwan, or Vietnam. These countries have existing fabrication infrastructure, personnel, and material supply chains to manufacture the prosthetic arms for minimal cost. However, the distribution costs are high compared to a product made in the country of sale. If the prosthetics were to be manufactured in Afghanistan, the distribution costs would be minimal but there would be a larger up-front capital cost to build and operate a manufacturing facility. Since the prosthetic would likely strengthen the Afghanistan economy, a government subsidy would greatly improve the accessibility of the product. The government involvement could be in the form of sales tax breaks, reduced import tariffs, or research funding.

The sale price of the prosthetic will need to satisfy cost of production while also remaining assessible to the low-income amputee population of Afghanistan. Once the product is built and in use, the maintenance costs must be taken into consideration. If there are components that are likely to fail at foreseen times in the product life cycle, a cheap component that is easily accessible and easy to replace must be designed and perhaps provided with the initial purchase of the prosthetic.

References

[1] E. Strait, Lower Limb Prosthetics in Developing Countries…………………………8. 2006.

[2] “Afghanistan – Political process,” Encyclopedia Britannica. [Online]. Available: https://www.britannica.com/place/Afghanistan. [Accessed: 20-Jan-2019].

[3] “Prosthetics in Resource-Limited Countries – OPEDGE.COM.” .

[4] Ł. Jaworski and R. Karpiński, “BIOMECHANICS OF THE HUMAN HAND,” vol. 3, no. 1, p. 6, 2017.

[5] V. Faulkner, M. Field, J. W. Egan, and N. G. Gall, “Evaluation of High Strength Materials for Prostheses,” p. 15.

[6] A. Mota, “Materials of Prosthetic Limbs,” p. 7.

[7] B. L. Klasson, “Carbon fibre andfibrelamination in prosthetics and orthotics: some basic theory and practical advice for the practitioner,” p. 18.

[8] Z. S. Stys, “MECHANICAL ENERGY STORAGE,” in Energy Storage, J. Silverman, Ed. Pergamon, 1980, pp. 60–80.

[9] “US2582234.pdf.” .

[10] “US20170049583A1.pdf.” .

[11] “US20170266020A1.pdf.” .

[12] “CFR – Code of Federal Regulations Title 21.” [Online]. Available: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=890.3420. [Accessed: 19-Jan-2019].

Appendix A

A Gantt Chart was generated to provide a visual representation of the breakdown structure and the duration of each task for this project. Figure A 1 represents the Gantt Chart used.

A Gantt Chart was generated to provide a visual representation of the breakdown structure and the duration of each task for this project. Figure A 1 represents the Gantt Chart used.

Figure A 1 – A capture of the Gantt Chart used to plan this project.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removalRelated Services

Our academic writing and marking services can help you!

Freelance Writing Jobs

Looking for a flexible role?

Do you have a 2:1 degree or higher?

Study Resources

Free resources to assist you with your university studies!