Development of Nano Technologies

| ✅ Paper Type: Free Essay | ✅ Subject: Physics |

| ✅ Wordcount: 2756 words | ✅ Published: 11 Sep 2017 |

- Introduction

Extensive work has been put into the research of nanotechnology capabilities in the past decade and the findings have opened a new range of multi-functional materials in the industry. However, a major issue faced today is incorporating nano-particles into the final composite structure by using current infrastructure. New developments in the field, such as multifunctional materials with enhanced electrical, thermal and mechanical properties are required by several industrial applications. This review is an attempt at showing the most recent and representative performances of nano-enabling technologies reported in literature. The focus of this review is on the two main manufacturing technologies used in aerospace industry: Autoclave (or Pre-preg – pre-impregnated composite fibres), and Resin Transfer Moulding (RTM) technologies. It looks at several approaches used in the nano-enabling of composites for the aforementioned paths and presents the latest reported results from literature. Finally, this work shows the difference between available integration nano-technology and future developments that are currently in demand for aerospace applications.

Since the early ’90s, micro- and nano-phase in polymers have been successful ways to improve material performance in various structural (such as strength, stiffness, energy absorption and thermal stability) and non-structural functionalities (such as thermal conductivity, energy storage and structural health monitoring). There are mainly two routes to creating nano-enabled composites – nano-augmentation (random and homogenous distribution of nano-particles in the material) and nano-engineering (pre-organized distribution of nano-particles) [5]. These methods are considered the most promising in regards to multi-functionality – increased performance and integrating possibilities. [6]Such materials, also called hierarchical composites may gain new properties from nano-scale incorporation as well as benefiting from the advantages of traditional structural (Fig. 2). Since the early ’00s, significant economical efforts have been invested in the research of such innovative materials. The aerospace industry has been a leader in this development, requiring high performance materials with high durability to extreme environment conditions. Fibre reinforced composites are used in applications such as structural panels, satellite platform and solar array substrates. These applications can improve through nanotechnology with development in permeability for cryogenic tanks and durability to diffusion species, space station oxidation resistance, mechanical toughness against structure damage, high modulus for stable and precision structures, interlaminar shear strength for tubular structures, electrical conductivity for electrical dissipation and lightning strike protection, etc.[8]. In this review, nano-enabling of composites methods are presented from the processing and manufacturing point of view. The work’s perspective is focused on near term application. Firstly, all the steps of each technique are identified, and then the options available for nano-scale phase integration are evaluated. The evolving trends are presented alongside through reported performance of novel composite material systems. Lastly, the expected near and long-term progress is reviewed.

- Main Body

This review focuses on the two most commonly used technologies – Autoclave/ Prepreg and RTM. Prepreg technology is currently most used in aerospace industry for manufacturing high performance components while the latter is used as an alternative for large complex shapes. The differences between the two techniques can be observed in the state of the fibre reinforcement (dry or wet) and the curing methods (autoclave i.e. heating in a container, or out-of-autoclave curing). Most of the space structures are assembled from prepreg systems, which are set up on moulds and cured in an autoclave [3]. With RTM, the fibre that forms in dry state is preassembled to form the preform reinforcement and it is used for complex shapes that can be more readily made than other moulding techniques. With these methods covered, it is thought that the majority of composite production technologies for aerospace industry are addressed.

Pre-impregnated composite manufacturing route

This method is considered the most entrusted for producing high performance aerospace structures. Prepregs are very flexible, being able to cover various material needs given proper selection of the matrix and the fibre. Currently, due to the well-established prepregs, autoclave and automated laminating manufacturing industries, it is crucial to find methods that allow the incorporation of nanotechnology in prepregs without changing already developed steps in composite manufacturing. The conventional process for Autoclave Cured Prepreg Composite Manufacturing is mapped in Fig. 3. The process starts with the preparation of the available materials which are then manually or automatically laid-up with the required layers cut to the shape and size from the roll, based on the composite component requirements. Vacuum, combined with high temperature and pressure is used to assist a controlled resin flow in the elimination of entrapped air until the final cure of the part. Afterwards, when the temperature and pressure are brought to ambient levels, the part is demolded and tempering and finishing is applied. In some cases (for example high performance polymers), a post-curing cycle may be required.

Resin transfer molding composite manufacturing route

RTM can be used to describe various techniques in aerospace industry [10, 11], such as Vacuum Assisted RTM (VARTM) and Resin Film Infusion (RFI). Generally, RTM is a process that belongs to out-of-autoclave manufacturing, where liquid resin is injected in a dry fibrous enclosed preform until the final curing of the part. RTM is a cost effective process when the component production numbers are high (<100/year) and it is mainly used when certain complex design shapes are required. RTM has considerable design flexibility, the main effort being spent on the pre-design of the final production setup, so that it is easier to add additional small steps that will perform the nano-enabling of the composite material. The map of the production steps is presented in Figs. 4 and 5. The process starts the same way, with the preparation of the available materials that are then layered up and cut to shape and size. In this process there is a parallel preparation needed, where the resin parts are prepared. A preform of the fibrous reinforcement is assembled and preheated if required then positioned and supported onto the molding tool. Once the resin mixture is prepared, the impregnation of the preform takes place with the aid of pressure and/or vacuum. Afterwards curing of the part takes place using ambient or elevated temperature followed up by demolding and post-processing if required.

Nanotechnology integration in existing manufacturing routes

Nano-enabled composites must have the nano-phase integrated in the final cured composite. In both processes the integration seems simple in the initial stages of the chain, but more complex concepts take place at later stages, with both routes experiencing drawbacks to be detailed later.

Nanotechnology integration in prepreg manufacturing routes

For the autoclave cure pregreg route, the concepts for nanomaterial integration will be carried out in the initial stages (i.e. between Raw Materials and Lamination). The nanomaterial can be a part of raw materials or be involved in lamination, the easiest being in stage I, however, it is suggested that an intermediate step between stages I and II may be best suited for introduction of nanomaterials.

This modification stage can include [14]: thin film lamination [15], resin films [16], particle deposition, nanopolymer spinning and printing. After lamination there are very limited possibilities of including nanomaterials, namely applying nano paint which may only affect the aesthetics and not the performance.

Nanotechnology integration in resin transfer molding route

Similar to the prepreg process, nanotechnology integration can be carried out in the initial stages. (Fig. 7) Nanomaterial can be involved with the resin or fibres in the raw material stage. In a resin, nanomaterial can be homogenously distributed, but this presents obstacles as the material viscosity is changed affecting stability. Introduction of nanomaterials during the fibre phase is an alternative option that can take place before resin injection. [23] This can be done via carbon nanotubes (CNT) deposition on the fabric [24] that can carry the nanomaterial, or by strengthening the fibre by circular growth of CNT. [25] The process of nano fibre sizing may deliver the nanoparticles directly to the fibre mix as part of the composite. [26]

The advantage of RTM path is that nano integration can take place even at the preforming stage. At this stage the multiple layers are constructed to form a body. There are many options of integrating the nanophase at this stage, for example, the use of nano-reinforced polymer films with the aid of nano-augmented solutions that are sprayed in a pattern on material, adding reinforcement. An additional step between the preforming and injection stage can also be used as an alternative integration method.

Following on from the discussion of processing, information on the practical forms of the products and the nanotech involved are presented in the following table.

Performance of nano–enabled composites

The advantage of nano-enabled composites is that they extend horizontally by delivering multiple property improvements at once. As previously stated, CNT have been the starting point but a variety of additional nano-fillers such as CNF and nano-SiC, has been proposed and employed, to reach the desired performance. In recent years Graphene seems to be one of the most promising fillers in the nanocomposites field. [49] The synergy between the nanoparticles of identical or compound materials (hybrid) are also promising. [50, 51]. Generally, the volume fraction of the reinforcing phase and its control is critical for the performance of composite material. Until present time, the major interest for nano-enabled composites has been related to the mechanical, electrical and thermal properties, as they reflect the improvement needs from the current technology.

Mechanical properties

In mechanical performance, nano-technology is expected to improve the out-of-plane properties of composites. Fibre-dominated properties, such as strength and stiffness, are already high, thus the addition of nano-phase is not expected to improve the situation. Nonetheless, flexural strength improved with the introduction of CNTs. [54] Unless there is a key change in the production of fibres, it is thought that nanotechnology will not have a consistent direct effect on strength and stiffness.

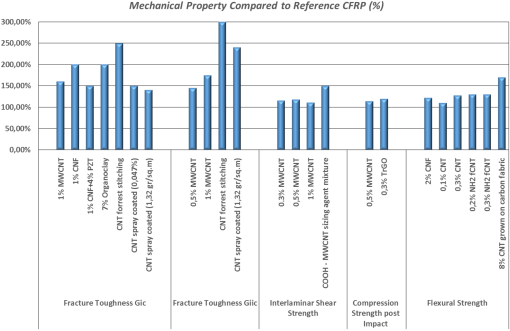

Better results can be found in matrix-dominated and out-of-plane properties, such as shear strength, fracture toughness and impact damage resistance. Most of the current nanotechnology integration methods have a direct effect on these properties, as shown in Figure 21.

Electrical properties

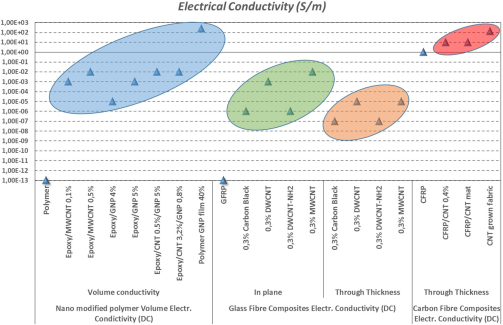

Electrical properties were one of the first interests of nanocomposites. Aerospace application needs lie in electrical conductivity developments to allow current flow and charge dissipation through the structure, expected to be 1-10 S/m in all directions in the composite. Impressive results have been obtained in polymer mixtures. This is because the dispersed nanotubes form a conductive network for electron flow [68].

Glass fibre reinforced polymers (GFRP) with ~0.3% composition of CNTs exhibit directional electrical conductivity, i.e. ~10-2 S/m in-plane and ~10-5 S/mthrough thickness. [2, 55] These results match the expected performance. Graphene polymeric sheets have been used with ~250 S/m. Electromagnetic interference (EMI) shielding properties have gained improvements as a side result of conductivity efficiency developments. [72] Some of the results are shown in Figure 22.

Thermal properties

Following from the results in electrical properties, research and application has been devoted to thermal properties as well. Even though thermal conductivity has been believed to have similar nanocomposite performance as electrical conductivity, reports have not confirmed the expectations. The effect of low filler loading on the thermal conductivity of polymers is negligible [75], as is the case with metal powder particles modified epoxies [76]. The reason there is a difference in response from conductivity in thermal and electrical nano-particles is that their conduction is carried out in different ways. Electrical conduction is achieved through electrons, and thermal conductivity is achieved through phonons. In recent research study it was revealed that the dominating factor in thermal conduction of composites is the Kapitza resistance in the interface regions of the different phases of the composite [77]. These interface regions promote phonon scattering and blocks heat transfer. The presence of such high number of interfaces in nano-composites may prove an obstacle in for achieving thermal conductivity improvements. Nevertheless, higher contents of conductive fillers, alignment of fillers, functionalization, hybridization and mixing of thermally conductive fillers, can result in synergestic effects that may bring the desired results as it has been shown [51, 78, 79].

Multifunctionality

The results reviewed address a range of nano-enabling techniques and attempt to reveal the most representative improvements on structural and non-structural properties. This is done in an ad-hoc manner, essentially disregarding the parallel effects and influence in other properties. The key for advanced composites in the future will be the combined selection and design of nano-materials for achieving a combined multifunctional performance. This multifunctional perspective of composites is their competitive advantage and should be treated as a tool for design by engineers. The common factor for this performance design is the processing and manufacturing techniques which have rigorously been discussed and analyzed in the previous paragraphs. The improvement reported on structural performance influencing properties (such as fracture toughness, ILSS, damping, etc.) if combined with the improvements reported on non-structural functionalities (such as electrical conductivity, sensing, thermal conductivity, thermal dimensional stability, etc.) which has been achieved by the incorporation of nano-particles in composites concludes to the result that neFRP composite materials could be delivered with overall enhanced performance. To demonstrate this multifunctional perspective of nanoenabled composites and the enhancement of multifunctional performance that can be achieved, Table 2 assembles the results on various properties reported in literature for three different nano-enabling approaches as defined in [61]: (A) bulk resin, (B) fiber-matrix interface and (C) interlaminar modification. Figure 26 attempts to illustrate schematically the multifunctional perspective of neFRPs.

- Conclusions

After more than a decade of studies and promising results and a variety of applications, it is clear that the technology of nanomodification to deliver structural composites has reached a crucial milestone towards its short-term utilization. This milestone represents the need to transform from lab scale to industrial scale. A gap has been identified between available nano-integration routes and already established FRP processing and manufacturing technologies to reach a seamless integration of nanotechnologies in production units. Table 3 summarizes the challenges that nanotechnologies and certain approaches need to overcome in order to increase their Technology Readiness Level and near the application in spacecrafts or space missions. Successfully crossing this gap would secure a stable transition from the planning phase to the application phase where solid benefits and practical use of the technology are understood.

|

Challenge |

Description |

|

Incompatible production scale |

The proposed approaches work well at lab scale but investment on new production lines and processes are required to bring these technologies to industrial production |

|

Compatibility with existing production methods |

Many of the proposed technologies require alternations in the supply chain and the production processes or at best special handling conditions |

|

Materials used are very specific |

Results achieved are specific on the materials used and are not transferable to industrially used materials |

|

Commercial availibility and proprietary information |

Commercial availability of the materials is limited or restricted for certain products (e.g., resins, fibers) |

|

Quality assurance in industry |

Quality assurance measures are not yet defined for such nano-enabling processes and in some cases may violate already established standards |

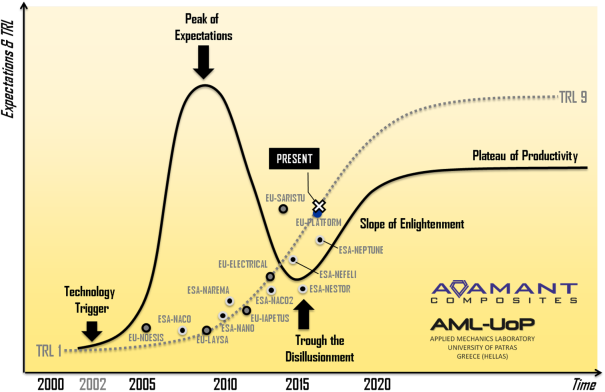

From a manufacturing point of view, it is preferred not to introduce any dramatic changes to the process in order to introduce the nano-phase inside the composites. Thus it is crucial that the nano-enabling product manufacturers develop products in raw to not drastically change the manufacturing processes as they are considered more adaptable by the industry. Certain properties have already been confirmed to improve while research for other is intensified. While significant progress has been made and apt results are available, wide acceptance and adoption in applications is yet to be realized [87]. To present graphically the evolution of the technology, both in terms of TRL growth and Hype Cycle [88], Fig. 27 has been formed.

The figure presents an estimation of the TRL evolution of nanotechnology for composites. It is combined with the hype curve which indicates the different stages of a new technology’s lifecycle. To assemble the diagram data were collected from the conclusions extracted from several key research programs supported by the European Space Agency and the European Commission (Framework Programme 7-Thematic: Aeronautics) and literature. The coordinates of each project point reflect the end year (X-coordinate) and the TRL at the end of the project (Y-coordinate). It can be concluded that nanotechnology for composites has reached a turning point in maturity and readiness level. Qualified products for the composites market based on nanotechnology to have already sprung out and more should be expected in the near future. As the hype moves into the slope of enlightenment, nanotechnologies will continue to get integrated gradually and, apart from the tertiary applications already attempted, these products are expected to find greater adoption in more critical secondary and primary applications. It is believed that in the following 5 years more space and aerospace space applications will benefit from composite products that incorporate nanotechnologies for improved performance; in one functional dimension, in a multi-functional dimension or as a system.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal