Effectiveness of Environmental and Occupational Health and Safety Hazards in Logistics Company

| ✅ Paper Type: Free Essay | ✅ Subject: Employment |

| ✅ Wordcount: 3953 words | ✅ Published: 23 Sep 2019 |

Environmental, Occupational Health and Safety Hazards and Change Programme

Introduction

The purpose of this report is to describes the effectiveness of Environmental and Occupational Health and Safety hazards in the organisation. It also focusses on the health and safety controls and the different methodologies that are used to manage these hazards. It also shows the strategies and results oriented approach for occupational health and safety risks towards opportunity for productive change and growth. This report is synthesised on the bases of personally conducted worksite visit. Mainfreight Logistics situated in Otahuhu, Auckland was chosen for research. The source of information gathered for research was online research, personal interview with the Health and safety Co-Ordinator, Operational manager, Staff member, to illustrate the understandings.

The purpose of this report is to describes the effectiveness of Environmental and Occupational Health and Safety hazards in the organisation. It also focusses on the health and safety controls and the different methodologies that are used to manage these hazards. It also shows the strategies and results oriented approach for occupational health and safety risks towards opportunity for productive change and growth. This report is synthesised on the bases of personally conducted worksite visit. Mainfreight Logistics situated in Otahuhu, Auckland was chosen for research. The source of information gathered for research was online research, personal interview with the Health and safety Co-Ordinator, Operational manager, Staff member, to illustrate the understandings.

Background of the Company

Mainfreight is a New Zealand based logistic and transport company headquarter in Auckland. It was founded by Bruce Plested on 6th March 1978. It offers supply chain solutions to both international and domestic freights and become one of the extensive freight company in New Zealand. It has its 250 branches around the world in Australia, China, Europe, and USA (Mainfreight, 2018). Mainfreight has its unique culture of successful doing its business not only in New Zealand, but also around the world. Mainfreight is responsible for crating safe working environment for their people.

Nature of Environmental health hazards

An environmental hazard is the state which has the potential to harm the natural environment as well as the human’s health. The environmental health hazards are affecting all the aspects of life and all the areas of practice such as Logistics (Lerner et al., 2015). The workplace is an important setting that needs to be considered while studying environmentally related illnesses, hazards and exposures in occupational settings. There are many categories of environmental health hazards such as biological, physical, cultural or practice related, chemical and social hazards. Physical hazards are those substances or conditions that might cause harm or threat the physical conditions among the people. Biological; hazards are the different types of organisms found in the environment that are potentially harmful for human beings (Environmental Hazards, 2018) Chemical hazards are said to be present while an individual is being exposed to harmful chemicals at home or at work. Cultural or practice-related are related to the culture and practice of such in an organization or a country that might cause adverse effect on the health and well being of the people. This report mainly focuses on the environmental hazards in one of the Mainfreight’s branch in Railway Lane Otahuhu. The branch has proper team to deal with health and safety hazards within the organisation. They had a Health and Safety Co-ordinator, First Aiders and DG Co-Ordinator. According to the Health and safety Pack of Mainfreight every branch has different hazards according to the different freight they are handling or dealing but the produce and methods to control the hazards are same bases on the nature of hazard. As per the Health and safety co-ordinator of Mainfreight there are different types of environmental hazards which are as follow:

- Air and Noise pollution

- Heat Stroke

- Earthquake

Link between Environmental Health and Occupational health and safety

Environmental health is a sector of public health specialty field that is directly connected to other aspects of both the built up and natural environments that further affects the health of the individuals and the population. The term “occupational health”, which is a subfield of environmental health deals with the health and safety issues in a workplace as well as has a strong focus on the prevention of the primary hazards that might cause injuries and diseases among the employees in the organization (Environmental and Occupational Health, 2018). Most of the environmental and occupational health practitioners usually carry out their jobs as detectives and inspectors who help in assessing and ensure safe water, food, good quality of air and sanitary conditions. They also assess and state the solutions for the prevention and control of hazards supervising the remedies of toxic waste as well as investigate and prevent outbreaks of different diseases including those which are caused by infectious and toxic agents, occurrence of natural disasters and bioterrorism. The increase in need for the environmental and occupational health comes from the threat of environmental and occupational health, including those who are associated with global warming and climate changes. These can be recognized as the effects of the indoor and outdoor pollution of air on cardiovascular and respiratory diseases, deadly outbreaks that are generally caused by food that have been contaminated with different types of germs such as E. coli, Salmonella and Listeria. There are diseases that can be spread out by means of unsafe drinking water and cancer-causing chemicals, toxins and other such agents.

Engineering, Work practice and Administrative Controls

The environmental and occupational hazards can effectively be controlled through identification of the critical agents, pathways and population who are risk. Monitoring such as performing routine assessments that are aimed at detecting the changes in the environment and health take into account a wide range of sources such as emissions from different sources, concentration of population in a specific area, measurements of specific agents, routine monitoring of relevant data regarding the health of people (Lundgren & McMakin, 2018). As mentioned in health and safety pack of Mainfreight when any significant hazards are identified a formal approach is required to dealing with them under the Health and Safety Employment Act. Organisation has to follow the practicable steps to eliminate the hazard by the following process below:

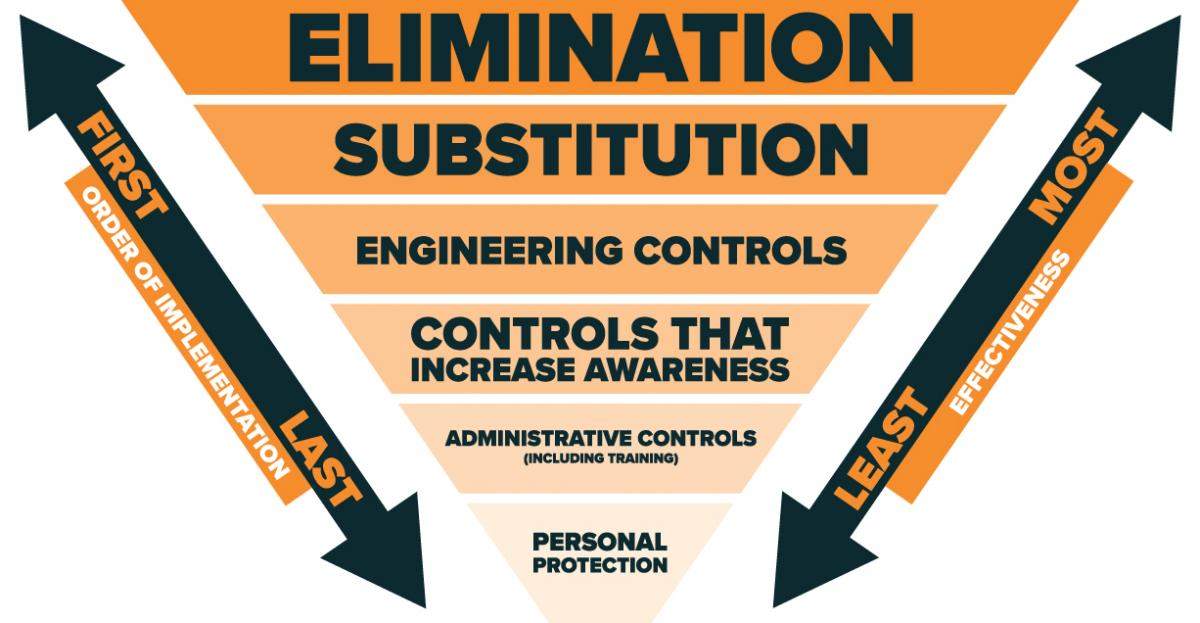

(Figure, Hierarchy of controls)

The above given figure shows the six different steps of Hierarchy control in the health and safety which are describes below:

Eliminate: Eliminate control is to remove the hazard physically. In Mainfreight, with the team members, the health and safety Co-ordinator list actions to eliminate or remove any significant hazard. For example, In the warehouse most of the time the Folk drivers has to pick stock from the higher levels or location. It can be hazard for them if they pick without any safety harness. So, the hazard can be eliminated by moving the stock to lower or ground location.

Substitute: In Mainfreight, if it is not possible to eliminate, try to isolate or substitute the hazard. Substitute is one of the effective controls that can replacing the hazard with something posing less risk. For example, using electric forklifts instead of gasoline Forklifts because electric forklifts are environment friendly and have zero emission. According to the Ohio study electric forklifts prevent almost 20,000 pounds of carbon monoxide discharged to the atmosphere. 97% of batteries of electric forklifts are also recyclable. (NMCMaterialhandling, 2018)

Engineering Control: Engineering controls are used frequently but they are effective as elimination. Engineering control may mean changing a piece of machinery or work process to reduce exposure to the hazard. For example, using proper machine guards, installation of additional lighting. There are number of control measure which called engineering control includes enclosure, isolation and ventilation.

Work practices: In Mainfreight safe work practices are the part of performance evaluation. Mainfreight promote safe work systems and focus on solid corrective actions. Organisation maintained the monthly report of accidents, incidents, spills, near misses’ events and discomfort & pain. It also engages all the team members from each area to hold and document the health and safety meetings. Training is also provided to all the team members to perform their roles in safe and healthy way. Drug and alcohol tests are also implemented randomly. Trail evaluation is also reformed in every six months to check fire hazard.

Administrative controls: According to Health and safety pack of Mainfreight, if the engineering controls are not enough then a process will need to be put in place to make the workplace safer. Mainfreight has established the policies, procedure and work practices designed to reduce a worker’s exposure to risk. Mainfreight has a policy to encourage every member of the organisation to participate in Health and safety training and PAT meetings. Every branch of Mainfreight had regular internal and external audits that includes competence in health and to evaluate the effectiveness in health and safety. Health and safety responsibilities are explained to all the new team members at their induction. When any team member is injured, their individual circumstances are managed and respected and will also be assisted with work options.

Environmental and job hazards

-

Air and Noise pollution:

Air for living life is very important but the polluted air can kill the human. Air pollution can be one of the major environmental hazards in Mainfreight. The main of air pollution is trucks. Mainfreight uses trucks for the delivery of the goods. Heavy commercial trucks for transportation caused produce more emission than cars. According to NZ transport almost 90% of emission came from diesel vehicles (Driving and air pollution, 2018). Another hazard is noise pollution. Driving trucks, Forklifts, Folk hoists create noise that can impact the human health. According to the H&S officer while loading and unloading heavy machinery cause noise. So, sometimes it is not easy to work under these circumstances to overcome this problem, organisation provide air mask and ear muffs for the safety of the people in the organisation.

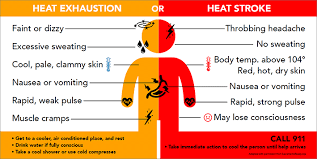

- Heat Stroke:

As discussed with the H&S officer another environmental hazard that impacts the human health is Heat Stroke. This hazard has the potential to cause organ failure. In Mainfreight there is a special team for deveining the containers which is Mainfreight Mobile. They are working outside environment and exposure to heat. I had a personal discussion with the container boys about this heating weather, they said this weather create lots of problems for them such as their body temperature raises due to heat and lost too much fluid, which makes them feel excessive thirsty, dehydrated, headache and dry mouth and eyes. Because of this it impacts their work also. Their speed of working gets impacted they feel sick and takes leave. But on the other hand, for the safety of the worker Mainfreight allow their team to devein the container under the roof and prevent them from Heat from Sun.

- Earthquake

A sudden movement of the earth’s crust caused by the released of stress collected along faults or by any volcanic activity. In Mainfreight, during an earthquake if anyone is inside the building they have to move away from the windows, equipment’s and shelves that may fall. Stay inside the building until the shaking stops or safe to exit. If someone is driving the forklift, he/she should use hand break and brace himself until the shaking stops. Organisation also has instruction after the earthquake. Everyone should keep alert because aftershocks often occur. Sometimes, electricity supply could be cut off and the fire alarms can also go off in the building so be aware of this. Do not use elevators, if you are in the damaged building use stairs to get outside, find safe and open place. Is anyone smell gas or hissing noise, turn off the gas and everyone should be getting out quickly as possible. In Mainfreight everyone has to be meet in the assembly area at gate number 3 and also report to the wire wardens and conduct head count. Contact on 111 if nay emergency service is required.

Job Hazards

In this part of the report, only discussed the job hazards associated with the Railway lane branch of Mainfreight because the other branches of Mainfreight had different job hazards which depends upon the nature of the clients they are dealing. For example, Chem courier is the part of Mainfreight group which is specialized only in dealing dangerous goods and hazardous substance. They have special truck constructed to LTSA (Land Transport Safety Authority), cages and bins, load locking devices and emergency response equipment. In railway lane branch there are different site-specific hazards, but three examples of job hazards are below:

- Freight falling from heights: Freight which is located on the height location can be the job hazard in the organisation. If the freight is not stacked and rapped properly it can be fallen on the team member. Organisation has the policy to minimise and control this hazard by rapping all the pallets going in to the racks on level 2+ height. Health and safety co-ordinator/ site supervisor and operational manager have the responsibility to review this.

- High level picking: Picking the products in the warehouse from high level is also the one of the job hazards. In this process team member can fall from the height and injuring themselves. In the safety pack of Mainfreight to control this hazard anyone who is driving the reach for picking should wear harness at all time while driving and even when driving around the warehouse.

- Blind Corners while driving forklifts: while using machines in warehouse and not looking the blind corners can cause injury to the team members. The potential harm with the blind corners is damaging the freight and hitting someone. There are also few methods to control this job hazard is Hi-Viz should be wearing all the time in the warehouse and pedestrians should make sure they stop after crossing a cut through in the warehouse. All the machines should sound the horn when approaching the blind corner. (Mainfreightlogistic, 2018)

Effectiveness of controls

Mainfreight has adopted the effective methods to control the hazards in the organisation. The different methods for controlling or recording the hazards are Mainfreight group hazard register, emergency procedure and plan in case of fire, earthquake and other hazards, Mainfreight logistic fire map for railway lane, fire wardens, shutting procedure for KiwiRail which is next to the branch, PPE control for safety of employees, Safety Co-Ordinators monthly inspection, Accident reporting, Mainfreight rehabilitation policy, Hazard Management Specialists such as Worksafe NZ, ACC partnership programme, DG Co-Ordinator monthly checklist, Mainfreight Guest and contractor Book. (Mainfreightlogistic, 2018)

- Maintain hazard register: Every Mainfreight group has their hazard register which is maintained by health and safety Co-Ordinator of branch. In this register all the potential hazards, harm, Significant hazard, monitoring process, Hierarchy of controls, team responsible to review hazards, how often does the control need monitoring and hazard last reviewed are recorded. For example, if using the electric hand tool, it can be the hazard, potential harm is electric shock, laceration, sprains and strains. Engineering and administrative control is required. To control this hazard, check electric leads for any defects, take extra care when using share edges, maintained and stored hand tools securely. Engineers are responsible to review this hazard and monitored annually. In Mainfreight railway lane this hazard was reviewed in May 2018.

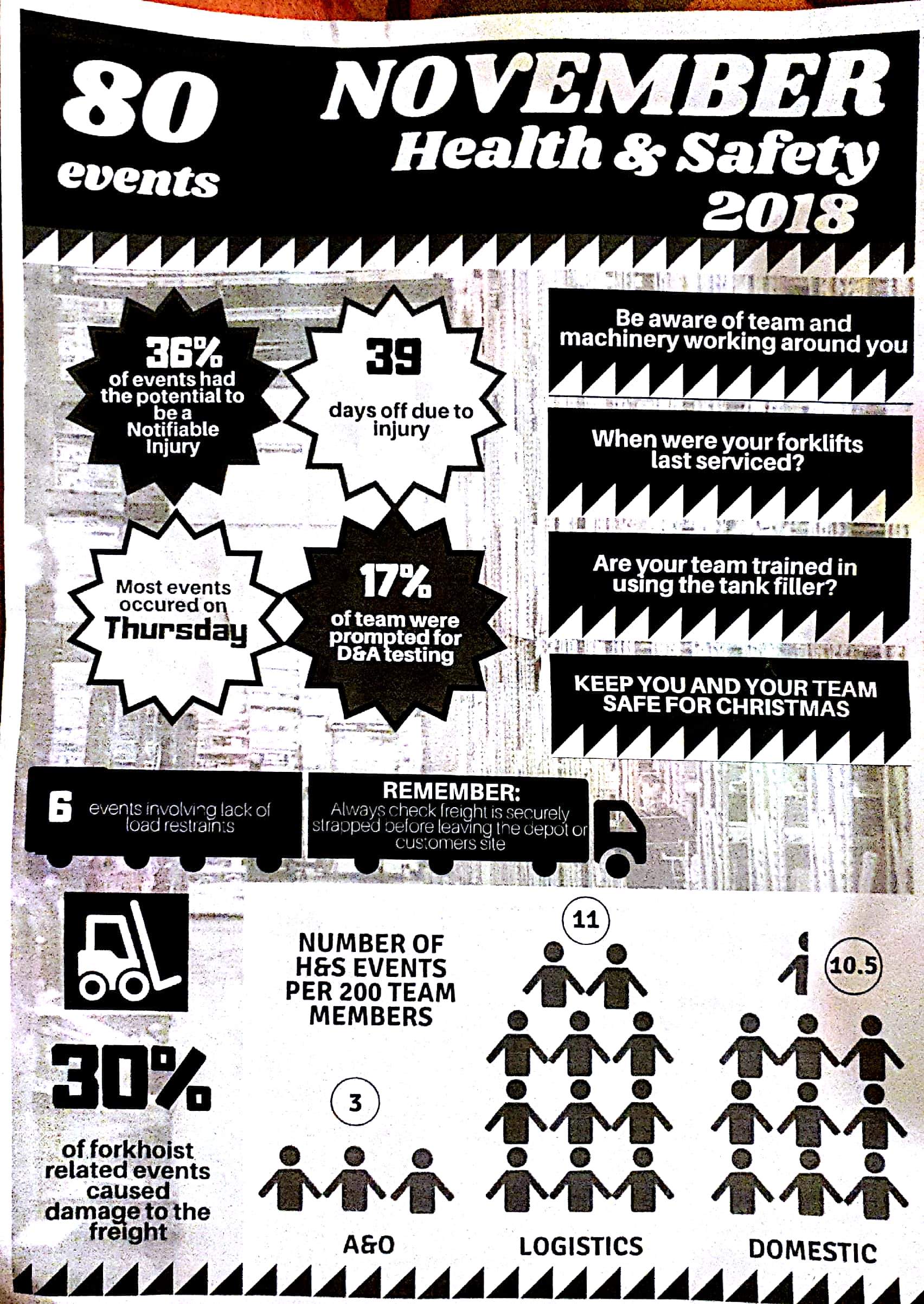

The below chart shows the November,2018 Health and Safety report of Mainfreight:

- Monthly inspection report: Health and safety Co-Ordinator of the branch has to inspect the site every month. This inspection include to check fire extinguishers, Exit doors, electrical switches, General lighting, Walkways, Rubbish (Bins located at suitable points and not overflowing), Depot Sweeping ( To check is the depot dust free), Storage, Floors, First Aid, Office, Display Material/ Training(i.e. H&S policy signed by Branch Manager and displayed on the Notice Board, Emergency Phone numbers, plan, Hazard Chart), Computers( Adequate room and height of desks), Product Handling Equipment, Waste Disposal/general cleaning, Preventative maintenance( i.e. Lifting equipment been tested and certified, check security gate motors, maintenance of storm water filters and drainage system), Pest management, general Housekeeping and monthly monitoring of significant Hazard. (Mainfreight, 2017). All these reports must be signed by Health and safety Co-Ordinator and Branch Manager of the site.

- Accident and Incident Produce: Mainfreight has the proper procedure if any accident or incident happened in the branch. There is the investigation flow chart describes in handbook of Mainfreight shows the procedure of investigate accident. There are four steps involve in the process:

a) Respond Accident/ incident (Report serious harm to Worksafe NZ, Medical treatment, notification of Accident form started)

b) Collect Information (Talk to the injured team member, talk to the other team members, what was the work activity at the time of accident, Were the correct procedure being used, check the equipment and environment)

c) Reporting: Ensure that the hazard must be recorded in the Mainfreight Hazard register and make sure the controls are appropriate.

d) Corrective Actions: To take the corrective actions, Health and safety officer must communicate with the injured team member, operation manager and appropriate team and discuss the accident in the PAT meeting. Ensure all the controls must be implemented for the hazard and monitor them if identified as a significant hazard.

- Rehabilitation Programme: Mainfreight has a rehabilitation policy mentioned in their Health and safety pack which must implemented effectively by taking following actions:

Team members:

a) Every team member has to inform about the injury to their team leaders and Health and safety officer within 12 hours

b) They have to be fully co-operated with the rehabilitation policy

Mainfreight:

a) Mainfreight must take all the reasonable steps to keep their team member at work again

b) They have to implement the processes in Rehabilitation Manual

All the appropriate modification to the equipment, work practices or duties are considered that allow a team member to remain at work. An individual rehabilitation plan will also be developed jointly by Mainfreight and the injured team member with in 14 days of cover being established where the rehabilitation needs. If any team member has taken the sick leave, all the leaves are managed and monitored by Mainfreight in accordance with the team member (Policies, 2017). Face to face or over the phone, meetings are held with the injured team member to discuss about their recovery/ rehabilitation.

- ACC Programme: Mainfreight is the accredited employer and agreed to assume ACC’s responsibilities. Mainfreight has contracted with GBNZ (Gallagher Bassett NZ who assist Mainfreight with injury management. Every year Mainfreight is audited by independent auditors and ACC to ensure the Health and safety& Injury management are in place. Out of three levels of the service determined by the result of audit, Mainfreight is currently secondary. The claim management period is 2 year after that file is returned to ACC because ultimately the claim belongs to ACC.

Capacity Building Framework, Strategic and result oriented Approach

Capacity building or the capacity development is defined as the process by which most of the individuals and organizations retain, obtain and improve the skills, tools, knowledge, equipment and other such resources which are required to do the jobs in the most competent manner. The capacity building is a conceptual approach towards social and behavioural changes that further leads to the development of the infrastructure. The factors that contribute effectively building of capacities include selection of better staffs, encouragement of the teamwork and motivating the employees by providing equal rewards for all the staffs. This also includes providing opportunities for the employees of the firm to work with different non-governmental organizations that helps in sharing of the different skills and ideas and helps in linking of the theories that have been learnt in the former days along with practice. The framework is often written as a mission statement, aims and the reasons of existence of the company (Capacity Building, 2018) This is the most useful way of thinking about the primary task. The strategies provide a focus for decision making as well as benchmark for the purpose of judging the point that a new idea or the project aligns with the proposed aim, mission and strategy. Leadership is the ability that helps in guiding, inspiring and taking people into account so that the aim and goals of the organization are achieved as well as helps in maintaining the capacity building strategy of the organization.

Training and Development: Every branch of Mainfreight invest in training and development programmes of their people. They provide better training to new people. For the growth of the company it become an important discipline. 100% of the team members are promotable in order to achieve the growth. Health and safety training is provided to everyone for the safety of themselves and people around them.

At the company analysed, there is a systematic approach to building a framework not only with the team members of the organisation but also all the contractor’s team members who come into for rendering any service, according to the characteristics of the jobs to be developed. (Mainfreight, 2018)

As Mainfreight is involved with Supply Chain and Transportation, there are lots of factors that need to be taken into consideration in order to get the aimed results and to achieve the requirements from Worksafe NZ. For that, every single team member of the company needs to be inducted on a personalised induction according to the nature of the business and the specific hazardous of the site and all the contractors will have a different type of induction depending on the type of services to be executed at the site. Every branch needs to have a Health & Safety Coordinator trained by an outside organisation as well as have enough people trained as First Aiders and Fire Wardens.

In the Logistics business, Team Leaders are instructed to be the responsible for the team members wellness, but during the induction all team members will be informed that they are responsible for their health and safety when at our premises and they are trained on their tasks and get the necessary licences for operating machinery if they are hired and still do not have a licence.

For the execution of the activities in the business, all Personal Protective Equipment (PPE) are available and also every team member is trained on an Operational Manual where all the main activities are outlined, and necessary training is provided.

There is a Hazard Management put in place comprised of 6 steps which are (Identify the hazard ——— Assess the risk ———–Control the risk———–Manage the controls ——– Monitor significant hazard ————– Review controls).

After the Hazard Management is done, a Site-Specific Hazard Identification Table is constantly updated where the following controls are monitored:

|

Hazard Number |

Hazard |

Potential Harm |

Significant Hazard (Yes/No) *if yes monitoring is required on the form |

Health Monitoring Required (refer glossary for meaning) |

Select eliminate, isolate, substitute or minimise the hazard |

Controls |

Team responsible for review of hazards |

How often does the control need monitoring (6 monthly or annually) |

Hazard last reviewed |

In case the answer for Significant Hazard is YES, Mainfreight needs to develop a specific Hazard Control Plan.

References

- Capacity Building. (2018). Retrieved from councilofnonprofits: https://www.councilofnonprofits.org/tools-resources/what-capacity-building

- Driving and air pollution. (2018). Retrieved from AA: https://www.aa.co.nz/drivers/speaking-up-for-drivers/driving-and-the-environment/driving-and-air-pollution/

- Environmental and Occupational Health. (2018). Retrieved from publichealth: http://www.publichealth.indiana.edu/departments/environmental-health/what-is-eh/index.shtml

- Environmental Hazards. (2018). Retrieved from omicsonline: https://www.omicsonline.org/scholarly/environmental-hazards-journals-articles-ppts-list.php

- Mainfreight. (2017, 11 10). Monthly Inspections. health&safety pack.

- Mainfreight. (2018). Retrieved from mainfreight: https://www.mainfreight.com/nz/en/nz-home/about-us.aspx

- Mainfreightlogistic. (2018, 08). Health and safety Handbook.

- NMCMaterialhandling. (2018, 10 09). THE ADVANTAGES OF AN ELECTRIC FORKLIFT. Retrieved from nmc-corp: www.nmc-corp.com/lift-truck/advantages-of-an-electric-forkli

- Policies. (2017, 11 02). Health and safety pack. Mainfreight.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal